news News from Cinnamon AI

- press

Launch of MITA solution service to accelerate DX in the manufacturing industry

Launch of MITA solution service to accelerate DX in the manufacturing industry

Promoting the maximization of the value of technical information through DX

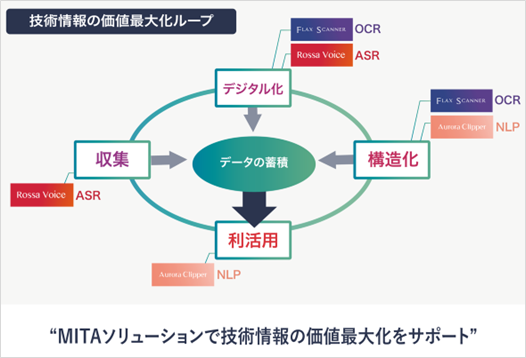

Collect technical data, proceed with digitization and structuring, and enter into a cycle of utilization and accumulation.

*MITA (Manufacturing Information Technical Asset)

From February 28, 2023, in order to accelerate the promotion of DX in the Japanese manufacturing industry, Manufacturing Information Technical Asset (hereinafter referred to as MITA Solution), a solution that increases the efficiency and scale of AI utilization by combining multiple AI models, will be launched. We will start providing services.

In an era of uncertainty, one of the current challenges for the domestic manufacturing industry is how to gain new competitive advantages for each individual company. Under these circumstances, if the "technical information" that has been accumulated so far can be "assetized (utilized and accumulated as needed)", the attractiveness of the company can be reaffirmed within the company, and skills can be passed on by sharing knowledge. It is possible to review services and operations, and promote development that can easily create synergies with current services. DX (Digital Transformation) is useful for visualizing, utilizing and accumulating "technical information" and maximizing its value, and Cinnamon AI will support the manufacturing industry with MITA solutions that accelerate DX promotion. .

You can download MITA solution materials here.

(URLhttps://go.cinnamon.ai/wp_mita_dl.html )

■What is MITA solution?

A multifaceted approach to data is essential to maximizing the value of technical information. MITA solutions collect information, digitize it, structure it, and put it to use. We will also create an "information asset loop" to realize the cycle of accumulation and utilization.

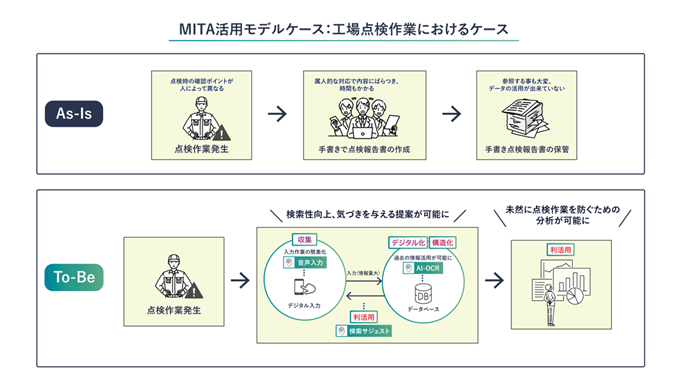

■MITA utilization model case

Model case for creating inspection reports in manufacturing factories

【assignment】

① Past data is managed on paper and cannot be utilized.

② Since the input is handwritten, it is not suitable for data accumulation. Furthermore, the amount of information is also small.

③ Because it is a personal management process, the writing style and checkpoints differ depending on the person. Improved work efficiency and leveled quality.

I haven't come yet.

[Ideal form]

1 Utilization of AI-OCR (digitization/structuring)

1.1 Read text information and effectively utilize past data (for search, reference, and analysis)

2 Utilization of ASR (collection/digitization)

2.1 Improved efficiency of input work and increased amount of information through voice input

3 Utilization of NLP (structuring/understanding/utilization)

3.1 Further expanding the range of data utilization by structuring data through specific extraction, classification, and named entity extraction

3.2 It is possible to suggest and recommend points to be careful of based on past data

3.3 Analyzing trends and countermeasures from past data using text mining

■About products related to MITA*We plan to expand our products in the future.

Flax Scanner for Technical Documents / AI-OCR for technical documents(Product name: Flax Scanner)

This is a product tuned for the manufacturing industry based on the AI-OCR "Flax Scanner," which boasts an accuracy of over 90% even for handwritten documents. As a result, it is possible to digitize technical documents, including specifications, drawings, manuals, accident and failure reports, etc., which are said to be highly difficult.

> Download materials from below

https://cinnamon.ai/new-cinnamon/industry/manufacturing/flax-scanner-for-technical-document/

Incident AI / NLP for past trouble information(Product name: Aurora Clipper)

For maintenance work in factories and plants, "Incident AI" uses text information related to many accidents, such as accident reports, near misses, and operating instructions, to identify highly related accidents, their causes, countermeasures, and results. It can be used as an analysis tool for making suggestions and for searching and creating reports. Aiming to break away from maintenance work that is individualized, we aim to improve comprehensive security capabilities in the security field.

> Download materials from below

https://cinnamon.ai/new-cinnamon/industry/manufacturing/smartsecurityservice/

Rossa Voice / ASR for manufacturing industry only(Product name: Rossa Voice)

By training our in-house developed speech recognition engine "Rossa Voice" specifically for the manufacturing industry, we are able to recognize technical terms and in-house terms with high precision. In the future, when the amount of information increases, we will support more data-driven decision-making by using voice to turn information into an asset, rather than relying solely on text records.

> Download materials from below

https://cinnamon.ai/new-cinnamon/product/rossa-voice/

For inquiries about Cinnamon AI, please use this form.

https://go.cinnamon.ai/inquiry.html